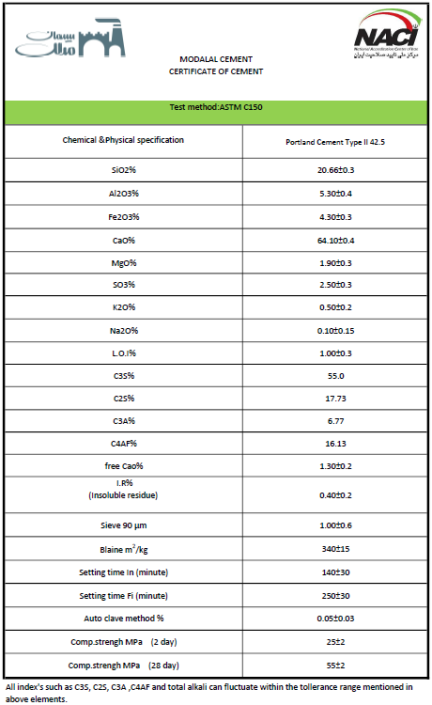

Portland cement type 2

Type II Portland Cement is a type of Portland cement designed for use in semi-corrosive environments. It has moderate resistance to sulfate attack and controlled hydration heat, making it suitable for certain conditions in construction and civil engineering projects.

Features

1. Moderate resistance to sulfates:

This cement performs well in environments where the soil or water contains moderate amounts of sulfate (for example, in areas where conditions are not highly corrosive but sulfate resistance is still required).

2.Lower heat of hydration:

Compared to Type 1 Portland cement, Type 2 cement generates less heat when setting and hardening. This feature is useful for large concrete pours such as dams or large foundations because it prevents heat-induced cracking.

3. Appropriate setting time:

The initial and final setting of this cement is such that it guarantees the efficiency of concreting under normal conditions.

4.Controlled chemical structure:

The lower amount of C3A (tricalcium aluminate) in the chemical composition of this cement provides greater resistance to sulfates and reduces heat generation.

Applications

Semi-corrosive environments:

Structures exposed to soil or water with moderate sulfate content, such as foundations and bridges.

Massive concreting

Construction of conventional structures:

Buildings, roads, and other civil engineering projects where sulfate resistance is required.

Structures buried in soil or underwater

Benefits

Increasing the durability of concrete:

In environments with mild chemical attacks, concrete produced with this cement is more durable.

Reducing thermal cracks